|

CONTACTS MACHINERY, INC. 25 ch. Schippel Montcalm, QC J0T2V0 PHONE: 866-514-0890 Contact Us About This Machine |

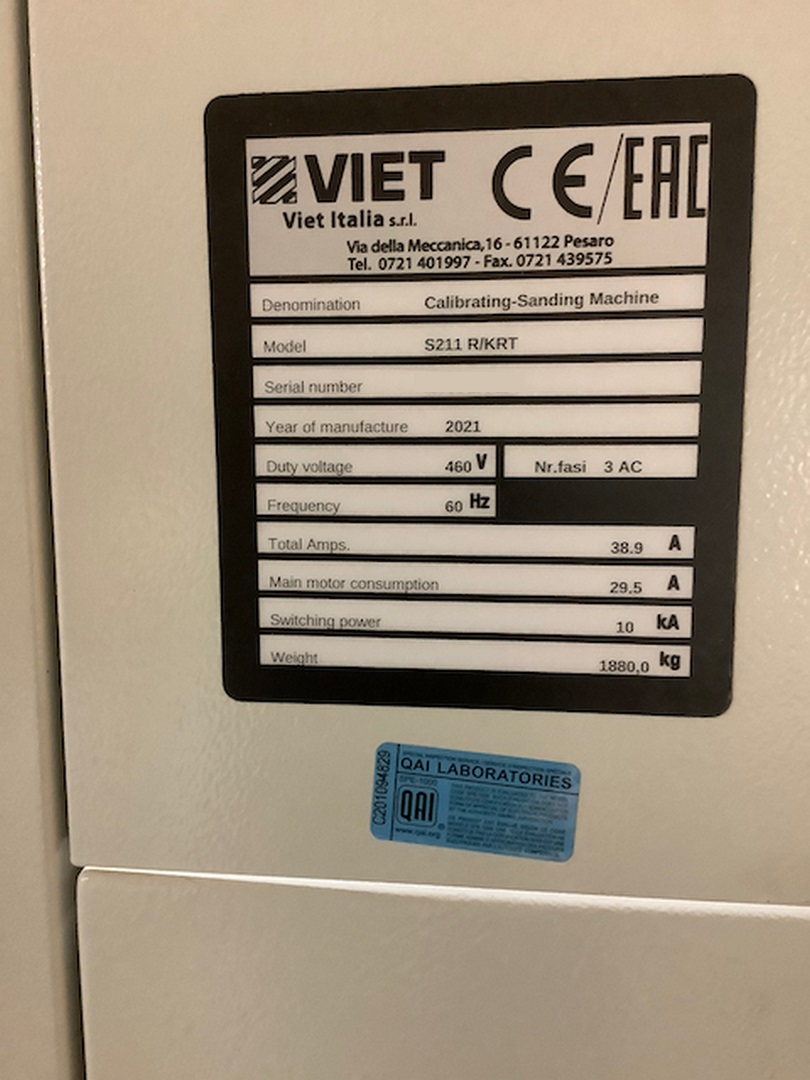

Viet S211 |

||||||||||||||

|

||||||||||||||

| Machine Information Sheet | Date: 4/27/2024 |

| Inventory #: | C5033TS |

| Machine Type: | Sanders - Planer/Wide Belt |

| Manufacturer: | Viet |

| Model: | S211 |

| Year: | 2021 |

| Region: | Eastern Canada |

| Voltage: |

460/3/60

Can be transformed to required voltage for a nominal fee. Single phase available thru a phase converter. |

| Condition: | Very Good |

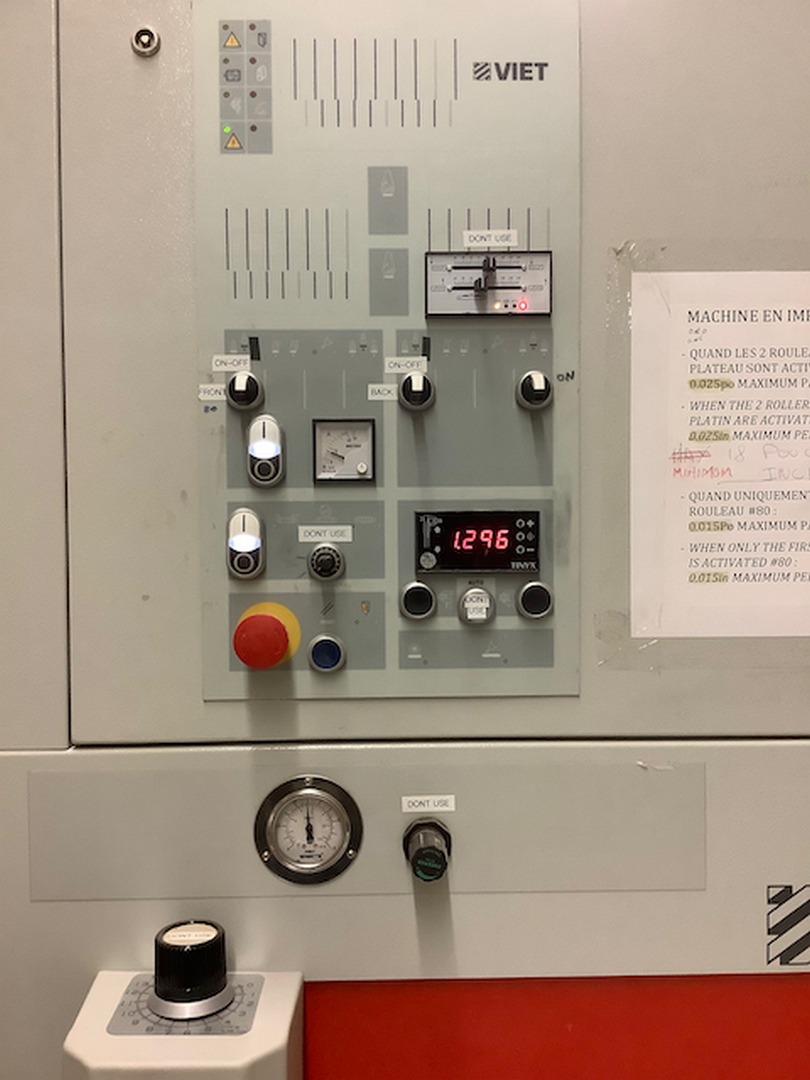

| Machine Capacities: | -Station 1: rollers -Station 2: electronic skate rollers -Transformer to 600V -Belt size: 44.5" x 75" -Height capacity: 3-160mm -Two-belt grader/sander, one motor and 1100 mm working width -Working unit #1 with roller -Working unit #2 with combined roller/skid unit General •Carbon steel frame made with electrically welded profiles •Rubber-coated vacuum rollers 55 SH with grooves •Design and construction of the machine in accordance with the provisions of the "Machinery Directive", CE marking •Replacing strips on the left side of the machine Electrical system •LED control panel for error visualization, star/delta operation of main motors automatic •Digital Viewer and Electronic Thickness Positioning System •Automatic star-triangle start of master notators •Padlockable general interswitch •Thermal protection for motors •Accessories on request •Motors with IP54 dust protection •Button Command • Manually operated thickness gauge Safety features •Emergency folding barrier at the entrance •Vacuum roller at the inlet with safety function, panel thickness and anti-reverse system •Autornal disc brakes on each group for quick emergency stop •Front and rear emergency stop push button Emergency Stops : •Abrasive belt breakage •Relaxed abrasive belt •Side outlet abrasive belt •Insufficient compressed air pressure •Overloading motors, abrasive belts, conveyor belts •Door openings •Material overthickness at the inlet •Pneumatic system •Electro-pneumatically controlled belt oscillation •Padlockable compressed air supply shut-off valve •Air filter with self-discharge condensation separator •Self-lubricating pneumatic components Rollers; •Made of steel, on eccentric shaft for adjusting the thickness of the abrasive belt •Rubberised coating with soft grooves and grinding of the contact surface with the abrasive belt. •Dust extractor hoods with profile designed for high performance •Manual adjustment and exclusion system •Tensioning rollers, steel abrasive belts, rectified and scales. •Anterior Presser - Rubber Roller (1 Roller) •Posterior Presser - Rubber Roller (1 Roller) Transport mat •Machined steel worktable •Lowering system of the worktable made with four large diameter trapezoydale screws •Motorized adjustment of the worktable •Conveyor belt made of 60 SH hardness rubber with ground flap surface •Worktable Expansion 1 Front Roller •Worktable Expansion 1 Rear Roller General Machinery •Sound insulation material •Usable working width: 1100 mm •Belt development 1900 mm •Installation to UL/CSA standards •PHTE400 •Operating voltage 460V/60Hz •Electro-pneumatically controlled belt oscillation 1° Roller unit •The roller workbench is characturised by precision and work efficiency of a very high level. Depending on the hardness of the rubber used and the diameter of the roller, the unit can be used for calibrating, sanding or sanding. The group is composed of: •A device for adjusting the grip of the wood and compensating for the difference in thickness between the abrasive belts. •The fixing of the ends and the support have been designed to obtain the maximum reliability of operation, excellent accessibility and ease of handling and high working precision •Electro-pneumatic transmission of the roller •Abrasive belt motor 18.5 kW {25 HP) 2° Roller Combo - Skate •The Kombi group (Viet patent 1967) makes it possible to have two contact tools on the same abrasive belt. Ideal for differentiating machining without having to add another group of work. •The roller workbench is characterised by precision and work efficiency. Depending on the hardness of the rubber used, the group can be used for calibrate, sand or sand. •The skate unit, thanks to a large contact surface, gives a guarantee of a level of Very high workmanship, the possibility of adjusting the working height of the skate allows to have a more or more high working pressure •Electro-pneumatic transmission of the roller •Electro-pneumatic skid lock + timed intervention •The device makes it possible to automate the descent and raising of the skid in such a way as to avoid the rounding of the front and back edges of the room Transport mat •Forward frequency inverter l .5kW (2HP) •Pneumatic belt centering •Entrance table extension (2 rollers) •Table extension at outlet (2 rollers) •Automatic thickness gauge with removal pre-selection •Electronic caliper detects panel thickness with an accuracy of 0.1 mm •Conveyor belt made of 60 SH hardness rubber with ground flap surface Controller •Button Command. The knob control panel allows the machine functions to be controlled with great ease and intuitiveness. The system is complete with automatic positioner for working thickness. |

| Sales Price: | CALL FOR PRICING |

| Contacts WW Machinery, Inc. sells pre-owned machinery on a first come, first served basis. Pre-owned machinery is not covered under any warranty or Government requirements. It is purchased "as-is - where-is, with all faults." Descriptions and specifications are to the best of our knowledge (some information is communicated via third party sources). It is strongly recommended that the machinery be inspected prior to purchasing to confirm the condition and specification. Additional charges such as crating and loading may apply. |